Hello and Welcome,

Before I begin, I would like to remind you to check the "Video Of The Week" section from time to time. I have added a couple very good videos in the past week. One is a tutorial about adjusting a rear index derailleur. The other is a video showing the proper way to skid your fixed gear bike. As of late I have been learning to ride my fixed-gear conversion. "The Skid" is a lot tougher than it looks in the video. This post is a direct result of my learning to skid experience.

Left Click On Image(s)to Enlarge.Use Back(<)Button to Return

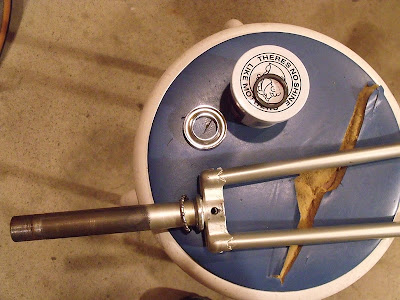

Above: Probably not the best stem for a fixed gear bike. Especially as the frame is about 5 or 6 cm too big for me, as is my belly. OK so I watched the "Skid Video" and thought "I can give this a shot". How hard can it be? Answer: Really Hard. As I pushed my considerable girth forward to take some of the weight off the rear wheel. I got this bugger poking me in my lower abdomen. I did manage a few really short (and painful) skids. Afterwords I knew I had to do something about this "Stem in the Gut" situation.

Above: This is a 6ft piece of foam pipe insulation, cost under 2.00 U.S. It is available in different sizes, So you should be able to find a good fit for your stem.

Above: All you need to cut this stuff is a fairly sharp pair of household scissors.

First bend it while holding it next to your stem and cut-off an approximate length piece. Don`t worry if it is a little long, you can trim it latter.

Above: The foam comes already split length wise. Centering the split towards the front of the bike cut a notch right at the point where the stem turns. You notice I cut the top angle different than the bottom. This is so the foam will will fit properly after it is folded and placed onto the stem.

Above: As you can see here I cut another notch in the foam tube so I could continue it all the way over the top of the handle-bar clamp. You can end yours where ever you want. If you don`t get it right the first time, No Worries, You still have another 5 feet of tube left.

Above: You can now tape it into place "as is" with electrical tape if you like. I`m going to coat mine with 3M Trim and Detailing Tape. Notice I have not taped over the fold area, I will do that last.

Above: Now I start applying the Trim Tape from the opposite end. I leave the area where the fold is untaped till last. Then I folded the tube and placed the last pieces of tape in place while keeping it folded. When finished it should hold it`s shape.

Above: Here you can see I cut the tape long enough to wrap the edges on the foam-tube. This should help it last longer and not soak up moisture on the edges. I did not worry about covering the bottom facing edge.

Above: Here I am checking the fit. Now I will pop it into place and secure it with pieces of the same trim tape.

Above: Here is the finished stem-pad. This one is literally "over the top" just like the graphics. Remember you can make yours any size and color you want. With the left-overs you can make stem-guards for the kids BMX or Mountain Bikes as well.

If you consider how many stem-guards you can make with a 6 ft piece of foam pipe insulation and one good roll of plastic trim tape. Well the cost per guard has got to be ridiculously low.

Enough with the Stem-Guard pictures already! That`s the last one, I promise.

***UPDATE*** Yesterday I removed the pad and lowered the stem. Then I trimmed the pad to fit. Why is it the simplest solution is sometimes the hardest one to find?

While the frame is still to tall for me, this is a huge improvement. I even managed to do a little skid in my driveway!

Until Next Time Please RIDE SAFE and Remember to always RESCUE, RESTORE & RECYCLE ..... Cheers, Hugh

Coming Soon! The Rock-Hopper FS gets some badly needed attention.

Friday, October 28, 2011

Monday, October 24, 2011

Fixed Gear Bike # 1 Finished

Hello and Welcome,

Before I start I would once again like to thank everyone who has checked-out the new Face-Book page for this blog. Considering the short time it has been up, I think it is doing pretty good. If you have not seen it yet, the link is in the right column. Just click on the logo "Hughs Bicycle Blog on Face Book" and you are there. Please show your support and click on "Like" while you are there.

Left Click on Image to Enlarge. Use Back(<)Button to Return.

Above: A reader asked me recently where I found the white replacement hoods for the aero levers on the Centurion. I told them I can`t find them in white either. I just clean-up the old ones and re-use them. I have had this old set laying around here forever. I had to cut-off the top to make it non aero. I then used an old brake lever mud-guard off a mountain bike to fashion a cable end that would hide the cut and keep out the debris/rain.

Above: The handlebars wrapped with Specialized S Tape. The cork tape behind the lever are actually 3 separate pieces, tucked under the hood. This works better with an adhesive backed tape. Then I wrap the tape from the flat about (4&1/2 centimeters from the stem) to the lever. Then finish with white electrical tape.

To keep the black cable end or (dust cover)in-place I used a little bit of 3M automotive emblem adhesive under the flap. This adhered it directly to the hood.

It would have been much easier to just use the correct hood, but unfortunately I did not have one on hand.

Above: The very inexpensive White Origin 8 Track/Road Bike Saddle looks great. Although I need to experiment with finding the correct height and pitch for me.

As it is right now, it is very uncomfortable. Even though it has the "comfort groove" and a narrow nose and seems to be well padded. I mean it looks like it would be reasonably comfortable. But it is not and I`m not sure why. So this time I will make an honest effort to adjust it to my needs or comfort zone. UPDATE: I decided to move the saddle forward and pitch it down in front just a hair. What a difference feels 100% better. I still think the WTB Speed V Comp is a little more comfortable though. But I`ll give it some time before I make a change.

Above: The TEC-9 single fixed-gear crank set with 170 mm arms and 46 tooth CNC machined chain-ring. Which like my 14 tooth cog takes a 1/8 chain. This was kind of a hassle to install, as the square-taper hole in the crank arms is a little too small. I could only thread the retainer nut on about 1/2 way. I decided to file the taper down a little. The hand file did not work at all, so I decided to use an mini angle grinder. I was careful to not flatten-out the pitch on the tapered bracket spline ends. Also I was careful to grind each of the four sides for the same time approximately. After each time around I would test fit the crank. After about four attempts I was finally able to tighten the retainer nut. I still have a little flaw or curve in the chain-line. But plenty of unused thread left on the bracket spline end to work with. I will most likely give it one or two more times around with the grinder. It is extremely important not to grind off too much from the bracket spline. Grind it too much and it will bottom-out and the bracket spline will be useless. That is why I test fit it each time after grinding. When I am finished I want it to still require lots of torque to secure it. And I want to make sure I still have some depth left. In other words I do not want the crank flush with the flat surface on the end of the spline. When I check it I still want to have some depth there.

Above: After it was finished I decided to replace the pedals as well. So I returned the old pedals the the Rock-Hopper FA. And took these new ones off the Rock-Hopper. It just looked so good I needed to finish it. I`m probably going to sell the Rock-Hopper FA in "as is" working condition. I have not had much luck in "getting my money back" on mountain bike builds. I really need to re-think what I will and will not replace on a Mountain bike build.

Above: I think re-painting the fork was really the only way to go. It was so badly scraped there was no way any amount of graphics was going to make it look acceptable. And with the white piping on the seat stays, I think it gave the whole

thing some balance. I may have gone a little overboard on the graphics. But that's the great thing about vinyl. If you don`t like it, just warm it up and peel it off and try again.

Ok enough about all that. Lets see some pics of the finished project.

Above: A nice shot of the drive side with the morning sun filling in the back drop

Above: A shot of the left side of the bike. And yes it does have a kick-stand.

Above: A shot from the right rear of the bike

Above: I found the stem very uncomfortable as I pushed my weight (200lbs) forward to practice my skid today. I managed to skid the bike three times. The first two times I picked an area on the paved path that was covered with wet leaves. I figured I needed all the help I could get. The third skid was on a damp sandy spot in the parking lot.

Well that's about all there is for now. After a brief search of the internet for a suitable stem pad. I decided to make my own. It actually came out "pretty fair" especially for my first attempt. I remember what a disappointment the last stem pad I purchased was. It was "all logo and not much padding", or as they say in Texas "All Hat and No Cattle". I will be posting the "Do it yourself Stem - Pad" real soon. Till then, RIDE SAFE and Remember to Always RESCUE, RESTORE & RECYCLE

Cheers,Hugh

P.S. Please check out the new "Video Of The Week" on How to Skid a Fixed Gear Bike.

You will find it in the right column near the top right under the Face-Book link. I think you will find it interesting.

Before I start I would once again like to thank everyone who has checked-out the new Face-Book page for this blog. Considering the short time it has been up, I think it is doing pretty good. If you have not seen it yet, the link is in the right column. Just click on the logo "Hughs Bicycle Blog on Face Book" and you are there. Please show your support and click on "Like" while you are there.

Left Click on Image to Enlarge. Use Back(<)Button to Return.

Above: A reader asked me recently where I found the white replacement hoods for the aero levers on the Centurion. I told them I can`t find them in white either. I just clean-up the old ones and re-use them. I have had this old set laying around here forever. I had to cut-off the top to make it non aero. I then used an old brake lever mud-guard off a mountain bike to fashion a cable end that would hide the cut and keep out the debris/rain.

Above: The handlebars wrapped with Specialized S Tape. The cork tape behind the lever are actually 3 separate pieces, tucked under the hood. This works better with an adhesive backed tape. Then I wrap the tape from the flat about (4&1/2 centimeters from the stem) to the lever. Then finish with white electrical tape.

To keep the black cable end or (dust cover)in-place I used a little bit of 3M automotive emblem adhesive under the flap. This adhered it directly to the hood.

It would have been much easier to just use the correct hood, but unfortunately I did not have one on hand.

Above: The very inexpensive White Origin 8 Track/Road Bike Saddle looks great. Although I need to experiment with finding the correct height and pitch for me.

As it is right now, it is very uncomfortable. Even though it has the "comfort groove" and a narrow nose and seems to be well padded. I mean it looks like it would be reasonably comfortable. But it is not and I`m not sure why. So this time I will make an honest effort to adjust it to my needs or comfort zone. UPDATE: I decided to move the saddle forward and pitch it down in front just a hair. What a difference feels 100% better. I still think the WTB Speed V Comp is a little more comfortable though. But I`ll give it some time before I make a change.

Above: The TEC-9 single fixed-gear crank set with 170 mm arms and 46 tooth CNC machined chain-ring. Which like my 14 tooth cog takes a 1/8 chain. This was kind of a hassle to install, as the square-taper hole in the crank arms is a little too small. I could only thread the retainer nut on about 1/2 way. I decided to file the taper down a little. The hand file did not work at all, so I decided to use an mini angle grinder. I was careful to not flatten-out the pitch on the tapered bracket spline ends. Also I was careful to grind each of the four sides for the same time approximately. After each time around I would test fit the crank. After about four attempts I was finally able to tighten the retainer nut. I still have a little flaw or curve in the chain-line. But plenty of unused thread left on the bracket spline end to work with. I will most likely give it one or two more times around with the grinder. It is extremely important not to grind off too much from the bracket spline. Grind it too much and it will bottom-out and the bracket spline will be useless. That is why I test fit it each time after grinding. When I am finished I want it to still require lots of torque to secure it. And I want to make sure I still have some depth left. In other words I do not want the crank flush with the flat surface on the end of the spline. When I check it I still want to have some depth there.

Above: After it was finished I decided to replace the pedals as well. So I returned the old pedals the the Rock-Hopper FA. And took these new ones off the Rock-Hopper. It just looked so good I needed to finish it. I`m probably going to sell the Rock-Hopper FA in "as is" working condition. I have not had much luck in "getting my money back" on mountain bike builds. I really need to re-think what I will and will not replace on a Mountain bike build.

Above: I think re-painting the fork was really the only way to go. It was so badly scraped there was no way any amount of graphics was going to make it look acceptable. And with the white piping on the seat stays, I think it gave the whole

thing some balance. I may have gone a little overboard on the graphics. But that's the great thing about vinyl. If you don`t like it, just warm it up and peel it off and try again.

Ok enough about all that. Lets see some pics of the finished project.

Above: A nice shot of the drive side with the morning sun filling in the back drop

Above: A shot of the left side of the bike. And yes it does have a kick-stand.

Above: A shot from the right rear of the bike

Above: I found the stem very uncomfortable as I pushed my weight (200lbs) forward to practice my skid today. I managed to skid the bike three times. The first two times I picked an area on the paved path that was covered with wet leaves. I figured I needed all the help I could get. The third skid was on a damp sandy spot in the parking lot.

Well that's about all there is for now. After a brief search of the internet for a suitable stem pad. I decided to make my own. It actually came out "pretty fair" especially for my first attempt. I remember what a disappointment the last stem pad I purchased was. It was "all logo and not much padding", or as they say in Texas "All Hat and No Cattle". I will be posting the "Do it yourself Stem - Pad" real soon. Till then, RIDE SAFE and Remember to Always RESCUE, RESTORE & RECYCLE

Cheers,Hugh

P.S. Please check out the new "Video Of The Week" on How to Skid a Fixed Gear Bike.

You will find it in the right column near the top right under the Face-Book link. I think you will find it interesting.

Wednesday, October 19, 2011

"Building Fixed Gear Bike # 1" Using Giant Built, Schwinn World (Tiawan) Lugged Frame

Hello and Welcome,

Before I start I would like to thank everyone who has checked-out the new Face-Book page for this blog. For the short time it has been up I think it is doing pretty good. If you have not seen it yet, the link is in the right column. Just click on the logo "Hugh's Bicycle Blog on Face Book" and you are there. Please show your support and click on Like while you are there.

Please Left Click on Pics to Enlarge. Use Back(<)Button to Return

Above: I was able to purchase the track wheel, 14 tooth 1/8 cog and lock-ring and the 1/8 chain for 83.00 including delivery. Except for the chain which I picked-up locally.

Above: After a quick bottom-bracket rebuild, in which I had to replace both cups and bearings. I mounted this 2 chain-ring, 3 piece crank. (after I removed the small chain-ring of course) It is a 3/32 width so the original 3/32 chain worked fine in front. But rode on top of the 14 tooth fixed cog. I had two choices, a wider chain and new crank or just order a 3/32 fixed cog. Being the 3/32 crank is bent, it was a no brainer. So I ordered a 1/8 single crank and picked-up the 1/8 chain locally. Besides I think the 1/8th set up is the correct way to go. And I don`t know enough about fixed-gear bikes to be "cutting corners". (pun intended)

Above: In this pic with the new 1/8th chain, the chain -line looks pretty good. But the chain is sloppy "side to side" on the crank. This is because a road bike chain-ring is made to fit a 3/32 road chain. I rode it like this after a quick mock-up and it seemed ok. Although at this point I had not yet rebuilt the head-set. I just gave the head-set bearings a quick smear of grease for now. I wanted to make sure this thing is going to go together ok before I do the total rebuild. It also has used tires on it for the mock-up and at this point I had not trued the wheels either. I am also using a scrap saddle and no tape on the handlebars.

Above: This pic is how I discovered the problem with the road crank. After examining all the pics carefully. I noticed in this pic the chain-line looks terribly bad. The problem is that "the crank is bent". When the drive-side arm in about the One o'clock to Three o'clock position the chain moves away from the frame. So that is how I discovered the bent crank. Once again taking digital pics of the job in progress has proven to be very helpful.

So I ordered a "Fixed Gear Crank Set" 170mm (arm length) 46 tooth w square taper.

Above: The frame is scratched much worse than it looks in this pic. And the fork is even worse. All the graphics (decals) are in rough shape as well. So I decided to make my own graphics that would cover-up the damaged graphics and most of the paint scratches as well. Being a blue bike, I decided to go with a patriotic red white and blue theme. And by placing stars all over the frame in a random "non-pattern" I will able to hide countless nicks and scratches.

Above: Not bad for my first attempt. But the huge "Schwinn like" red graphic on the fork looks awful. And still does not hide enough of the scratches and scrapes. So to match the white piping I did on the seat stays I decide to remove the fork and paint it white as well. I drew all the stars by hand on 3M trim tape and razor cut each one myself. The first ones were a little rough, but after a while they improved.

Above: As Roadie Ryan suggested I flopped and Chopped the handlebars and did the road brake-lever top mount thing. Being a true fixed wheel conversion, it will only have a front brake. *And I Do Not Advise Anyone To Do The Same* This time I cut the bars with a hack-saw. I think I was able to do a better job with the saw over the pipe/tubing cutter. Being that I was cutting right in the center of the curve where the bars are not always perfectly round. And using a pipe-cutter on an out of round pipe is tricky at best. Well, I opted for the hack saw and it gave me a better cut while not affecting the roundness of the bar pipe in a negative way.

I sanded the fork down right after Michigan lost to Michigan State in football Saturday. It was a good way to get rid of my aggression. Before spraying the primer I was careful to remove all the dust possible from the metal. I used a cleaning wipe followed by a dry wipe. And gave it a little time to air-dry before spraying.

In the cool weather I always allow extra time for the paint or primer to dry.

Above: The following day I was able to spray the paint outside, despite having to spray in between wind gusts. After spraying I moved the fork and stand back into the shop and turned up the heat for a while. About 7 hours latter I moved the fork into the house to cure over night. At this point it was no longer tacky but the paint did not feel totally dry either. At some point during this process the tires arrived. I could not be more pleased at how it is coming together so far.I did degrease the bearings and cups and re-built the head-set properly before installing the fork. I also trued the wheels, polishing and greasing the front. The front wheel is a good match even though it is salvaged.

Above: I think the white fork gives the color scheme some balance. I will be removing my blog sticker from the top tube and adding some graphics,possibly some white piping. And I`m not 100% sold on the brake lever type or location. So you may be seeing some change there as well.

Above: While I had the front-end apart I cleaned-up the reflector mount bracket with the fine brass wheel brush. Afterwords I gave it a quick coat of Turtle Wax Chrome Polish / Rust Remover. The white saddle has just arrived and I did exchange the black cork tape for white. The only other hold-up is the crank. But I have been told it is en-route.

Above: These pedals are used take-offs. I like the way they feel, I think I will be

keeping them on the bike permanently. And, It does not hurt that they were free as well.

Above: I did not take this brake caliper apart before polishing it, like I normally do. Can you see the difference? I sure can. Please, Let me know what you think.

That's all I`m going to show you until I get this thing 100% finished. But that should be real soon. Until Next Time.. Please Ride Safe & Remember to Always RESCUE,RESTORE & RECYCLE.

Cheers,Hugh

Before I start I would like to thank everyone who has checked-out the new Face-Book page for this blog. For the short time it has been up I think it is doing pretty good. If you have not seen it yet, the link is in the right column. Just click on the logo "Hugh's Bicycle Blog on Face Book" and you are there. Please show your support and click on Like while you are there.

Please Left Click on Pics to Enlarge. Use Back(<)Button to Return

Above: I was able to purchase the track wheel, 14 tooth 1/8 cog and lock-ring and the 1/8 chain for 83.00 including delivery. Except for the chain which I picked-up locally.

Above: After a quick bottom-bracket rebuild, in which I had to replace both cups and bearings. I mounted this 2 chain-ring, 3 piece crank. (after I removed the small chain-ring of course) It is a 3/32 width so the original 3/32 chain worked fine in front. But rode on top of the 14 tooth fixed cog. I had two choices, a wider chain and new crank or just order a 3/32 fixed cog. Being the 3/32 crank is bent, it was a no brainer. So I ordered a 1/8 single crank and picked-up the 1/8 chain locally. Besides I think the 1/8th set up is the correct way to go. And I don`t know enough about fixed-gear bikes to be "cutting corners". (pun intended)

Above: In this pic with the new 1/8th chain, the chain -line looks pretty good. But the chain is sloppy "side to side" on the crank. This is because a road bike chain-ring is made to fit a 3/32 road chain. I rode it like this after a quick mock-up and it seemed ok. Although at this point I had not yet rebuilt the head-set. I just gave the head-set bearings a quick smear of grease for now. I wanted to make sure this thing is going to go together ok before I do the total rebuild. It also has used tires on it for the mock-up and at this point I had not trued the wheels either. I am also using a scrap saddle and no tape on the handlebars.

Above: This pic is how I discovered the problem with the road crank. After examining all the pics carefully. I noticed in this pic the chain-line looks terribly bad. The problem is that "the crank is bent". When the drive-side arm in about the One o'clock to Three o'clock position the chain moves away from the frame. So that is how I discovered the bent crank. Once again taking digital pics of the job in progress has proven to be very helpful.

So I ordered a "Fixed Gear Crank Set" 170mm (arm length) 46 tooth w square taper.

Above: The frame is scratched much worse than it looks in this pic. And the fork is even worse. All the graphics (decals) are in rough shape as well. So I decided to make my own graphics that would cover-up the damaged graphics and most of the paint scratches as well. Being a blue bike, I decided to go with a patriotic red white and blue theme. And by placing stars all over the frame in a random "non-pattern" I will able to hide countless nicks and scratches.

Above: Not bad for my first attempt. But the huge "Schwinn like" red graphic on the fork looks awful. And still does not hide enough of the scratches and scrapes. So to match the white piping I did on the seat stays I decide to remove the fork and paint it white as well. I drew all the stars by hand on 3M trim tape and razor cut each one myself. The first ones were a little rough, but after a while they improved.

Above: As Roadie Ryan suggested I flopped and Chopped the handlebars and did the road brake-lever top mount thing. Being a true fixed wheel conversion, it will only have a front brake. *And I Do Not Advise Anyone To Do The Same* This time I cut the bars with a hack-saw. I think I was able to do a better job with the saw over the pipe/tubing cutter. Being that I was cutting right in the center of the curve where the bars are not always perfectly round. And using a pipe-cutter on an out of round pipe is tricky at best. Well, I opted for the hack saw and it gave me a better cut while not affecting the roundness of the bar pipe in a negative way.

I sanded the fork down right after Michigan lost to Michigan State in football Saturday. It was a good way to get rid of my aggression. Before spraying the primer I was careful to remove all the dust possible from the metal. I used a cleaning wipe followed by a dry wipe. And gave it a little time to air-dry before spraying.

In the cool weather I always allow extra time for the paint or primer to dry.

Above: The following day I was able to spray the paint outside, despite having to spray in between wind gusts. After spraying I moved the fork and stand back into the shop and turned up the heat for a while. About 7 hours latter I moved the fork into the house to cure over night. At this point it was no longer tacky but the paint did not feel totally dry either. At some point during this process the tires arrived. I could not be more pleased at how it is coming together so far.I did degrease the bearings and cups and re-built the head-set properly before installing the fork. I also trued the wheels, polishing and greasing the front. The front wheel is a good match even though it is salvaged.

Above: I think the white fork gives the color scheme some balance. I will be removing my blog sticker from the top tube and adding some graphics,possibly some white piping. And I`m not 100% sold on the brake lever type or location. So you may be seeing some change there as well.

Above: While I had the front-end apart I cleaned-up the reflector mount bracket with the fine brass wheel brush. Afterwords I gave it a quick coat of Turtle Wax Chrome Polish / Rust Remover. The white saddle has just arrived and I did exchange the black cork tape for white. The only other hold-up is the crank. But I have been told it is en-route.

Above: These pedals are used take-offs. I like the way they feel, I think I will be

keeping them on the bike permanently. And, It does not hurt that they were free as well.

Above: I did not take this brake caliper apart before polishing it, like I normally do. Can you see the difference? I sure can. Please, Let me know what you think.

That's all I`m going to show you until I get this thing 100% finished. But that should be real soon. Until Next Time.. Please Ride Safe & Remember to Always RESCUE,RESTORE & RECYCLE.

Cheers,Hugh

Tuesday, October 11, 2011

Motobecane Nomade Restoration Part 2

Hello and Welcome,

First I would like to say Thanks to the folks who have been using the blogs face-book page. If you have not checked it out yet, Please do. The link is located in the column on the right. (just click on the logo) I look forward to seeing more of your projects and favorite rides.

Left Click on Images to Enlarge, Click on Back(<)Button to Return

Above: While taping the handlebars on the MotoBecane I had an idea. Why not just roll the tape out to the end of the roll. Then tape the end into place with a small piece of tape. Then I can do the end wrap (elictrical tape) where I choose, then cut off the excess with a razor blade. I think it might be easier for some "like myself" who struggle with making the final cut then taping it into place.

The tape I used was slightly adhesive(Avenir) So there was no need for a small piece of tape on the end to secure it while I did the end wrap.

Above: Here I am cutting off the excess tape after getting the finish electrical tape in place. All you need to do is use the tape edge as your guide. Of course you will want to measure the other side to match before applying the finish tape. In this case I decided 4-1/2 cm looked about right. UPDATE: Anonymous said...

Be aware that if you score the handlebars when you trim, you run the risk of weakening the bars there. This is more likely with alloy, rather than steel bars.

Above: I think this method makes it easier for almost anyone to get a nice clean finish cut on the tape ends. You will need to be very careful cutting with a razor blade. I used a single edge blade. To ensure the best cut, I would recommend using a fresh blade each time. You can still use the blades for something else so your not really being wasteful. If you are not confident using a sharp razor blade, then Please get someone experienced to help you.

Above: I always thought of Jenson USA as a high-end supplier. I was pleasantly surprised to find this very affordable saddle on their site. And the delivery was extremely fast. So check them out next time your shopping online for components. You may be pleasantly surprised too! I picked this Avenir 100 Series saddle for style and price. If your building a road bike for resale you might want to consider this. A saddle is a very "personal preference" kind of thing. To me it does not make sense to invest too much into a saddle that is likely to be replaced anyway. Of course if your building a bike "to order" that is a whole different ball of wax.

Above: This is the best part of the build, getting some pics of the finished project out in the light of day. And this is my favorite angle to photograph a bike from, shooting slightly downward from the front drive side.

Above: Shooting the bike from down low close-up will make it look larger than life.

Susan from Segar Studio taught me that. I was able to scrounge up the corresponding front wheel reflector and the matching rear reflector as well. I hit the screw heads on the wheel reflectors with the brass wire wheel brush. And I cleaned them up with Armor All Cleaning Wipes. It really makes them pop!

Above: A nice shot from the port side. Looking at this pic I notice I did not put a dust cap on the left side of the crank. Opps! The dust cap on the left pedal is not correct. I crimped a larger MKS cap and popped it on there just for these pics.

Above: This is where taking the brake calipers apart and polishing them with Mother`s really pays off. The bolt head on the cable hanger was cleaned-up with the brass wheel brush. And the hanger itself and straddle cable were cleaned-up with Mother`s. I really love that stuff!

Above: Everything I said about the brake caliper holds true for the crank as well.

Looking at this crank makes me want to wrap the whole thing up and keep it clean.

But they are made to ride.

Above: A nice shot of the non original Araya front wheel. The correct reflector gives it a more authentic look. I do have a (sort of) set of Motobecane wheels. Front 1972 Rear 1976. I made this choice deliberately. I`m not a huge fan of the dimpled braking surface on the original wheels. Or the "electric motor sound" they make while braking. I did the same thing on my MotoBecane Special Sport. That`s how I ended-up with two usable Motobecane wheels. I know they will be put to good use somewhere down the road.

Above: The rear wheel and the beautiful Suntour Superbe derailleur. It is a thing of beauty. I also opted to remove the pie-plate while servicing the hub and free-wheel. I have in the past changed the free-wheel from a five to a six after removing the pie-plate. I did not do it in this case, I just thought I would throw that out there FYI.

Well I think that about covers it. Right now I am building a fixed gear bike. (trying to anyway) I did not have much to choose from in the frame department so I chose a tall blue Schwinn Sprint (Taiwan lugged frame)that has been hanging on the wall forever. I think I need to pick-up a single-speed chain as the ten speed chain is not quite wide enough. I should have something to report on that soon.

Above: There it is in the top left corner. Actually the blue Schwinn might be a Schwinn World not a Sprint. I`ll get back to you on that.

Till Next Time, RIDE SAFE and Remember to Always, RESCUE,RESTORE & RECYCLE!

Cheers, Hugh

First I would like to say Thanks to the folks who have been using the blogs face-book page. If you have not checked it out yet, Please do. The link is located in the column on the right. (just click on the logo) I look forward to seeing more of your projects and favorite rides.

Left Click on Images to Enlarge, Click on Back(<)Button to Return

Above: While taping the handlebars on the MotoBecane I had an idea. Why not just roll the tape out to the end of the roll. Then tape the end into place with a small piece of tape. Then I can do the end wrap (elictrical tape) where I choose, then cut off the excess with a razor blade. I think it might be easier for some "like myself" who struggle with making the final cut then taping it into place.

The tape I used was slightly adhesive(Avenir) So there was no need for a small piece of tape on the end to secure it while I did the end wrap.

Above: Here I am cutting off the excess tape after getting the finish electrical tape in place. All you need to do is use the tape edge as your guide. Of course you will want to measure the other side to match before applying the finish tape. In this case I decided 4-1/2 cm looked about right. UPDATE: Anonymous said...

Be aware that if you score the handlebars when you trim, you run the risk of weakening the bars there. This is more likely with alloy, rather than steel bars.

Above: I think this method makes it easier for almost anyone to get a nice clean finish cut on the tape ends. You will need to be very careful cutting with a razor blade. I used a single edge blade. To ensure the best cut, I would recommend using a fresh blade each time. You can still use the blades for something else so your not really being wasteful. If you are not confident using a sharp razor blade, then Please get someone experienced to help you.

Above: I always thought of Jenson USA as a high-end supplier. I was pleasantly surprised to find this very affordable saddle on their site. And the delivery was extremely fast. So check them out next time your shopping online for components. You may be pleasantly surprised too! I picked this Avenir 100 Series saddle for style and price. If your building a road bike for resale you might want to consider this. A saddle is a very "personal preference" kind of thing. To me it does not make sense to invest too much into a saddle that is likely to be replaced anyway. Of course if your building a bike "to order" that is a whole different ball of wax.

Above: This is the best part of the build, getting some pics of the finished project out in the light of day. And this is my favorite angle to photograph a bike from, shooting slightly downward from the front drive side.

Above: Shooting the bike from down low close-up will make it look larger than life.

Susan from Segar Studio taught me that. I was able to scrounge up the corresponding front wheel reflector and the matching rear reflector as well. I hit the screw heads on the wheel reflectors with the brass wire wheel brush. And I cleaned them up with Armor All Cleaning Wipes. It really makes them pop!

Above: A nice shot from the port side. Looking at this pic I notice I did not put a dust cap on the left side of the crank. Opps! The dust cap on the left pedal is not correct. I crimped a larger MKS cap and popped it on there just for these pics.

Above: This is where taking the brake calipers apart and polishing them with Mother`s really pays off. The bolt head on the cable hanger was cleaned-up with the brass wheel brush. And the hanger itself and straddle cable were cleaned-up with Mother`s. I really love that stuff!

Above: Everything I said about the brake caliper holds true for the crank as well.

Looking at this crank makes me want to wrap the whole thing up and keep it clean.

But they are made to ride.

Above: A nice shot of the non original Araya front wheel. The correct reflector gives it a more authentic look. I do have a (sort of) set of Motobecane wheels. Front 1972 Rear 1976. I made this choice deliberately. I`m not a huge fan of the dimpled braking surface on the original wheels. Or the "electric motor sound" they make while braking. I did the same thing on my MotoBecane Special Sport. That`s how I ended-up with two usable Motobecane wheels. I know they will be put to good use somewhere down the road.

Above: The rear wheel and the beautiful Suntour Superbe derailleur. It is a thing of beauty. I also opted to remove the pie-plate while servicing the hub and free-wheel. I have in the past changed the free-wheel from a five to a six after removing the pie-plate. I did not do it in this case, I just thought I would throw that out there FYI.

Well I think that about covers it. Right now I am building a fixed gear bike. (trying to anyway) I did not have much to choose from in the frame department so I chose a tall blue Schwinn Sprint (Taiwan lugged frame)that has been hanging on the wall forever. I think I need to pick-up a single-speed chain as the ten speed chain is not quite wide enough. I should have something to report on that soon.

Above: There it is in the top left corner. Actually the blue Schwinn might be a Schwinn World not a Sprint. I`ll get back to you on that.

Till Next Time, RIDE SAFE and Remember to Always, RESCUE,RESTORE & RECYCLE!

Cheers, Hugh

Thursday, October 6, 2011

Motobecane Nomade Restoration Part 1

Hello and Welcome,

I found this Motobecane Nomade about 35 miles from here in my hometown of RoyalOak Mi. I paid considerably more than I normally would for this bike. However it is not that often I run across a mid 70`s Moto. in this condition.

Above: As nice is this bike is, it does have a few issues. Most notably the pedals are missing. Common these days, but not so in the mid 1970`s (at least not here). Also the front wheel has been replaced with a generic steel wheel. The rear derailleur has been up-graded to a Sun Tour Superbe Tech. I will be posting a link to an article about the Sun Tour Superbe Tech on the "Bicycle Related Links" list.

Above: The chain stay accounts for about 94% of the paint touch-up. In other words, the paint is in wonderful original condition. There is also a little paint touch-up to do around the seat tube collar (about 5%). The other 1% is in a few spots around the frame. "All in All" One of the cleanest mid 70`s frames I have seen in quite a while.

Above: As always I rebuilt the bottom bracket and took the crank/chain-rings apart. Each part "including the spacers" was cleaned and or polished. I like how the plating on the ring-guard was done to match the aluminum alloy chain-rings and arms.

Above: The bearings, cups and bracket are all in very good shape. I de greased everything and re-assembled it."after re-greasing of course" I did add a plastic protector or shroud to protect the bracket when I re-assembled the unit. I left the drive-side cup in place. To clean the drive-side cup, I just loosen the work-stand clamp on the frame (top tube) and tilt the frame a little. Then I can spray the Clean-Streak right inside the bracket housing holding the cleaning pot underneath to catch the drippings. Before screwing the left side cup into the shell I wrapped the threads with Teflon Tape. I thread the cup into the housing about 1/8 inch before I wrap the threads with the Teflon. It is just easier for me to do it that way.

Above: Before sliding the crank into place and tightening the retaining nut, I put a little blue "Thread-Lock" on the threads. I think the three piece crank looks really good. Looking at it now, I guess I should have installed a new dust-cap before taking the pic. I`ll try to remember that next time.

Above: Some of the bearing cups had stubborn grease rings after spraying them with Clean-Streak. To clean these and the crown-race I used the Mother`s Mag and Aluminum Polish. Note: I always lightly grease the "Steerer" Tube and lower Stem (below the insertion line) and wedge-nut before assembly.

Above: The Stem all polished-up with Mother`s. I used Turtle Wax Chrome-Polish / Rust Remover on the Stem bolt. There was also some light rust on the wedge-nut and lower stem-bolt. As well as some "rust-staining" on the lower stem. The fine brass "wheel brush" on the 18 volt rechargeable low-speed drill made quick work of that.

Above: As the wheel-set was miss-matched, I decided to replace them with this Araya wheel-set. The rear wheel has a Sun-Tour 5 speed free-wheel, which is a good match with the upgraded Sun-Tour rear derailleur. I am pleased that the Araya front wheel has a quick-release skewer. I will also replace the rear axle nuts with (M) nuts off the original rear axle. That should bring it all together nicely.

Above: Here is a shot of the rear wheel with the Sun-Tour Superbe Tech derailleur cleaned and mounted. As you can see I have also installed the new chain. I like to establish a basic drive train as soon as possible. The tires are PanaRacer Pasela Tour-Guards 27 x 1 (ISO 25-630) 115.0 psi. Yes, they are small and fast. And I got a fantastic deal on them as well.

Above: I had to include a close-up of this beautiful Superbe Tech derailleur. I bet they "snatched these up" in the early 1980`s when they hit the market.

Above: This is an older model of basically the same Huret derailleur that was on the bike. The original functioned fine but had some deep pitting on the chrome. So I cleaned-up this one (left-over from the Special-Sport build) and it works and looks fine. I almost installed an old Simplex, just because I like the mechanism. But I just could not "get past" the dull finish on the Simplex. Besides the Old Simplex makes an interesting knick-knack.

Above: The front brake, broke down and ready for cleaning and polishing. On all the alloy parts I used Mother`s. As for the chrome parts I used the Turtle-Wax. And for the plastic parts I used Simple Green (bio-degradable de greaser) The Mother`s also works well on the straddle cable. And all the nuts and bolts were cleaned-up with the brass wheel brush. As always, I did the calipers one at a time, using the other caliper for a reference. To wheel brush the nuts it is easier to brush them if you screw then onto a bolt. Keep the nut flush with the end of the bolt and the brush will do a better job.

Above: The front caliper all cleaned-up and re-mounted on the bike with a new set of jag-wire shoes. It is possible to clean-up calipers without breaking them down.

But to get them "as clean and shiny as possible" you really need to take them apart. Besides, There is "no better way" to learn how something works, than to take it apart and put it back together again. Even if you "get stuck" and have to go to your local bike shop for help, You will still learn. If you do have to go to the local bike shop, tell them you want to watch the assembly. Most techs and shop owners are happy to share their experience. If not, Go somewhere else! However, You should call ahead (ring them up). And ask "what would be the best time to come to the shop when you would have time to show me what I need to do". I know I would appreciate that. And be more likely to help that person out.

Above: The rear brake incorporates the rear reflector mount into the installation. This is a little trickier but no big deal. I am not happy with the pitting on the mount bracket. I will try to locate another chrome one in the shop. I`m sure there is one around here somewhere.

Above: I have cleaned-up these vintage English road pedals. I think they were on the old Team Raleigh Record. Who`s frame still hangs from the shop rafters, waiting for me to be inspired. I am considering using it for my track bike build. But I think the old girl deserves better than that. And there is another matching dust-cap on the way! A Special Thanks to John Fink for that.

Above: I have polished-up the original 25.5 seat-post. I was considering a micro adjust post. But the only one I could find was anodized orange with a sleeve. So for now I`m going with the original. I am also going with the original handlebars.

They are in good shape and cleaned-up real good. I also polished-up the original levers and cleaned the black hoods. When finished she will have black hoods and black cork infused thick handlebar tape. And all black cable housings and a sleek black racing saddle. And all new jag-wire cables as well.

Above: The Simplex shifters. In a perfect world I would install Sun-Tour shifters and a Sun-Tour front derailleur to complete my Sun-Tour drive-train. But as I paid too much for this bike going in, I have to be realistic. But I will say this, I do like the Simplex "adjust on the fly" shifters. Who knows? maybe I`ll run across another donor bike. Well that`s about all I have for now. The saddle has been shipped by Jenson USA. I ordered this saddle Sunday night and received my item has been shipped e-mail Monday! You can`t beat that with a stick! So Thanks to JENSON USA! Well done! I should have "The Nomade finished" post up by early next week, if not sooner.

And I have come-up with a simple technique that I think might make cork handlebar tape finishing (cutting and taping) easier for the beginner. So watch for that on my next post.

Until Next Time, Ride Safe and Remember to Always... RESCUE, RESTORE & RECYCLE

Cheers,Hugh

I found this Motobecane Nomade about 35 miles from here in my hometown of RoyalOak Mi. I paid considerably more than I normally would for this bike. However it is not that often I run across a mid 70`s Moto. in this condition.

Above: As nice is this bike is, it does have a few issues. Most notably the pedals are missing. Common these days, but not so in the mid 1970`s (at least not here). Also the front wheel has been replaced with a generic steel wheel. The rear derailleur has been up-graded to a Sun Tour Superbe Tech. I will be posting a link to an article about the Sun Tour Superbe Tech on the "Bicycle Related Links" list.

Above: The chain stay accounts for about 94% of the paint touch-up. In other words, the paint is in wonderful original condition. There is also a little paint touch-up to do around the seat tube collar (about 5%). The other 1% is in a few spots around the frame. "All in All" One of the cleanest mid 70`s frames I have seen in quite a while.

Above: As always I rebuilt the bottom bracket and took the crank/chain-rings apart. Each part "including the spacers" was cleaned and or polished. I like how the plating on the ring-guard was done to match the aluminum alloy chain-rings and arms.

Above: The bearings, cups and bracket are all in very good shape. I de greased everything and re-assembled it."after re-greasing of course" I did add a plastic protector or shroud to protect the bracket when I re-assembled the unit. I left the drive-side cup in place. To clean the drive-side cup, I just loosen the work-stand clamp on the frame (top tube) and tilt the frame a little. Then I can spray the Clean-Streak right inside the bracket housing holding the cleaning pot underneath to catch the drippings. Before screwing the left side cup into the shell I wrapped the threads with Teflon Tape. I thread the cup into the housing about 1/8 inch before I wrap the threads with the Teflon. It is just easier for me to do it that way.

Above: Before sliding the crank into place and tightening the retaining nut, I put a little blue "Thread-Lock" on the threads. I think the three piece crank looks really good. Looking at it now, I guess I should have installed a new dust-cap before taking the pic. I`ll try to remember that next time.

Above: Some of the bearing cups had stubborn grease rings after spraying them with Clean-Streak. To clean these and the crown-race I used the Mother`s Mag and Aluminum Polish. Note: I always lightly grease the "Steerer" Tube and lower Stem (below the insertion line) and wedge-nut before assembly.

Above: The Stem all polished-up with Mother`s. I used Turtle Wax Chrome-Polish / Rust Remover on the Stem bolt. There was also some light rust on the wedge-nut and lower stem-bolt. As well as some "rust-staining" on the lower stem. The fine brass "wheel brush" on the 18 volt rechargeable low-speed drill made quick work of that.

Above: As the wheel-set was miss-matched, I decided to replace them with this Araya wheel-set. The rear wheel has a Sun-Tour 5 speed free-wheel, which is a good match with the upgraded Sun-Tour rear derailleur. I am pleased that the Araya front wheel has a quick-release skewer. I will also replace the rear axle nuts with (M) nuts off the original rear axle. That should bring it all together nicely.

Above: Here is a shot of the rear wheel with the Sun-Tour Superbe Tech derailleur cleaned and mounted. As you can see I have also installed the new chain. I like to establish a basic drive train as soon as possible. The tires are PanaRacer Pasela Tour-Guards 27 x 1 (ISO 25-630) 115.0 psi. Yes, they are small and fast. And I got a fantastic deal on them as well.

Above: I had to include a close-up of this beautiful Superbe Tech derailleur. I bet they "snatched these up" in the early 1980`s when they hit the market.

Above: This is an older model of basically the same Huret derailleur that was on the bike. The original functioned fine but had some deep pitting on the chrome. So I cleaned-up this one (left-over from the Special-Sport build) and it works and looks fine. I almost installed an old Simplex, just because I like the mechanism. But I just could not "get past" the dull finish on the Simplex. Besides the Old Simplex makes an interesting knick-knack.

Above: The front brake, broke down and ready for cleaning and polishing. On all the alloy parts I used Mother`s. As for the chrome parts I used the Turtle-Wax. And for the plastic parts I used Simple Green (bio-degradable de greaser) The Mother`s also works well on the straddle cable. And all the nuts and bolts were cleaned-up with the brass wheel brush. As always, I did the calipers one at a time, using the other caliper for a reference. To wheel brush the nuts it is easier to brush them if you screw then onto a bolt. Keep the nut flush with the end of the bolt and the brush will do a better job.

Above: The front caliper all cleaned-up and re-mounted on the bike with a new set of jag-wire shoes. It is possible to clean-up calipers without breaking them down.

But to get them "as clean and shiny as possible" you really need to take them apart. Besides, There is "no better way" to learn how something works, than to take it apart and put it back together again. Even if you "get stuck" and have to go to your local bike shop for help, You will still learn. If you do have to go to the local bike shop, tell them you want to watch the assembly. Most techs and shop owners are happy to share their experience. If not, Go somewhere else! However, You should call ahead (ring them up). And ask "what would be the best time to come to the shop when you would have time to show me what I need to do". I know I would appreciate that. And be more likely to help that person out.

Above: The rear brake incorporates the rear reflector mount into the installation. This is a little trickier but no big deal. I am not happy with the pitting on the mount bracket. I will try to locate another chrome one in the shop. I`m sure there is one around here somewhere.

Above: I have cleaned-up these vintage English road pedals. I think they were on the old Team Raleigh Record. Who`s frame still hangs from the shop rafters, waiting for me to be inspired. I am considering using it for my track bike build. But I think the old girl deserves better than that. And there is another matching dust-cap on the way! A Special Thanks to John Fink for that.

Above: I have polished-up the original 25.5 seat-post. I was considering a micro adjust post. But the only one I could find was anodized orange with a sleeve. So for now I`m going with the original. I am also going with the original handlebars.

They are in good shape and cleaned-up real good. I also polished-up the original levers and cleaned the black hoods. When finished she will have black hoods and black cork infused thick handlebar tape. And all black cable housings and a sleek black racing saddle. And all new jag-wire cables as well.

Above: The Simplex shifters. In a perfect world I would install Sun-Tour shifters and a Sun-Tour front derailleur to complete my Sun-Tour drive-train. But as I paid too much for this bike going in, I have to be realistic. But I will say this, I do like the Simplex "adjust on the fly" shifters. Who knows? maybe I`ll run across another donor bike. Well that`s about all I have for now. The saddle has been shipped by Jenson USA. I ordered this saddle Sunday night and received my item has been shipped e-mail Monday! You can`t beat that with a stick! So Thanks to JENSON USA! Well done! I should have "The Nomade finished" post up by early next week, if not sooner.

And I have come-up with a simple technique that I think might make cork handlebar tape finishing (cutting and taping) easier for the beginner. So watch for that on my next post.

Until Next Time, Ride Safe and Remember to Always... RESCUE, RESTORE & RECYCLE

Cheers,Hugh

Subscribe to:

Comments (Atom)